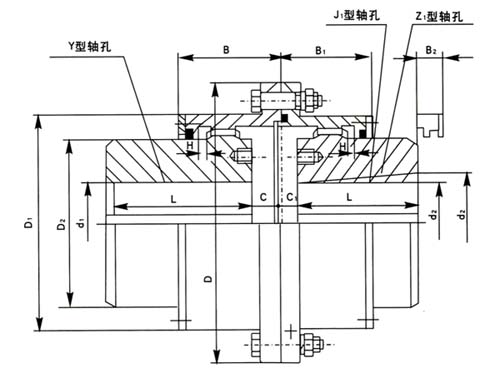

GIICLD型鼓形齿式联轴器(JB/ZQ4380-86)

注:由于市场价格时有波动,以下价格仅供参考,实际以销售人员报价为准,详情请拨打:13861821233

商品介绍

|

GIICLD型鼓形齿式联轴器基本参数和主要尺寸

|

型号 |

公称扭矩

Tn

(N·m) |

许用转速

[n]

(r/min) |

轴孔直径

d1 d2 |

轴孔长度 |

D |

D1 |

D2 |

C |

C1 |

H |

B |

B1 |

B2 |

转动惯量

(kg·m) |

润滑脂容量

(ml) |

重量(kg) |

|

Y |

Z1 J1 |

|

L |

|

GIICLD1 |

1000 |

4000 |

22 24 |

|

52 |

38 |

127 |

95 |

75 |

33 |

6 |

2 |

66 |

45 |

42 |

0.041 |

107 |

7.2 |

|

25 28 |

|

62 |

44 |

0.041 |

7.2 |

|

30 32 35 38 |

|

82 |

60 |

0.044 |

7.8 |

|

40 42 45 48 50 55 56 |

|

112 |

84 |

0.047 |

9.6 |

|

GIICLD2 |

1600 |

4000 |

38 |

|

82 |

60 |

149 |

116 |

90 |

33 |

6.5 |

2 |

70 |

49 |

42 |

0.085 |

137 |

11.2 |

|

40 42 45 48 50 55 56 |

|

112 |

84 |

0.097 |

14 |

|

60 63 65 |

|

142 |

107 |

0.106 |

16.4 |

|

GIICLD3 |

2800 |

4000 |

40 42 45 48 50 55 56 |

|

112 |

84 |

167 |

134 |

105 |

40 |

7 |

2.5 |

80 |

54 |

42 |

0.16 |

201 |

17.2 |

|

60 63 70 71 75 |

|

142 |

107 |

0.19 |

22.4 |

|

GIICLD4 |

4500 |

4000 |

45 48 50 55 56 |

|

112 |

84 |

187 |

153 |

125 |

41 |

7.5 |

2.5 |

81 |

55 |

42 |

0.29 |

238 |

25.2 |

|

60 63 70 71 75 |

|

142 |

107 |

0.33 |

26.4 |

|

80 85 90 |

|

172 |

132 |

0.38 |

35.6 |

|

GIICLD5 |

6300 |

3750 |

50 55 56 |

|

112 |

84 |

204 |

170 |

140 |

45 |

7.5 |

2.5 |

89 |

59 |

42 |

0.45 |

398 |

31.6 |

|

60 63 65 70 71 75 |

|

142 |

107 |

0.51 |

38 |

|

80 85 90 95 |

|

172 |

132 |

0.58 |

41.6 |

|

100 |

105* |

212 |

167 |

0.67 |

53.9 |

|

GIICLD6 |

9000 |

3300 |

55 56 |

|

112 |

84 |

230 |

186 |

155 |

52 |

8.5 |

3 |

106 |

71 |

47 |

0.75 |

465 |

40.5 |

|

60 63 65 70 71 75 |

|

142 |

107 |

0.840 |

49.8 |

|

80 85 90 95 |

|

172 |

132 |

0.94 |

56.3 |

|

100 110 |

115* |

212 |

167 |

1.07 |

67.5 |

|

GIICLD7 |

14000 |

3000 |

60 63 65 70 71 75 |

|

142 |

107 |

256 |

212 |

180 |

57 |

9 |

3 |

112 |

73 |

47 |

1.43 |

561 |

63.9 |

|

80 85 90 95 |

|

172 |

132 |

1.60 |

74.7 |

|

100 110 120 |

|

212 |

167 |

1.85 |

88 |

|

130 |

135* |

252 |

202 |

2.11 |

106.7 |

|

GIICLD8 |

20000 |

2650 |

65 70 71 75 |

|

142 |

107 |

287 |

239 |

200 |

49 |

8.5 |

3.5 |

112 |

82 |

47 |

2.24 |

734 |

81.7 |

|

80 85 90 95 |

|

172 |

132 |

2.51 |

95.5 |

|

100 110 120 |

|

212 |

167 |

2.88 |

114 |

|

130 140 150 |

|

252 |

202 |

3.25 |

123 |

|

GIICLD9 |

31500 |

2350 |

70 71 75 |

|

142 |

107 |

325 |

276 |

235 |

59 |

9.5 |

3.5 |

125 |

85 |

47 |

4.31 |

956 |

112 |

|

80 85 90 95 |

|

172 |

132 |

4.83 |

130 |

|

100 110 120 |

|

212 |

167 |

5.53 |

156 |

|

130 140 150 |

|

252 |

202 |

6.24 |

181 |

|

160 170 |

175* |

302 |

242 |

7.08 |

212 |

|

GIICLD10 |

45000 |

2100 |

75 |

|

142 |

107 |

362 |

313 |

270 |

76 |

11 |

4 |

149 |

95 |

49 |

7.88 |

1320 |

161 |

|

80 85 90 95 |

|

172 |

132 |

9.52 |

172 |

|

100 110 120 |

|

212 |

167 |

9.52 |

206 |

|

130 140 150 |

|

252 |

202 |

10.25 |

239 |

|

160 170 180 |

|

302 |

242 |

12.22 |

280 |

|

190 200 |

|

352 |

282 |

13.69 |

319 |

注:1、联轴器轴孔组合有Z1/J1、Y/J1。

2、带“*”号的轴孔直径新设计时不用。

|

|

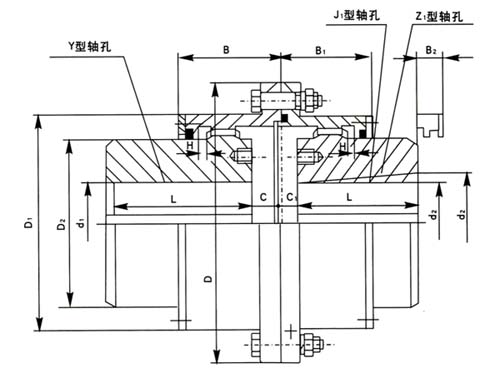

GIICLD型鼓形齿式联轴器基本参数和主要尺寸

|

型号 |

公称扭矩

Tn

(N·m) |

许用转速

[n]

(r/min) |

轴孔直径

d1 d2 |

轴孔长度 |

D |

D1 |

D2 |

C |

C1 |

H |

B |

B1 |

B2 |

转动惯量

(kg·m) |

润滑脂容量

(ml) |

重量(kg) |

|

Y |

Z1 J1 |

|

L |

|

GIICLD1 |

1000 |

4000 |

22 24 |

|

52 |

38 |

127 |

95 |

75 |

33 |

6 |

2 |

66 |

45 |

42 |

0.041 |

107 |

7.2 |

|

25 28 |

|

62 |

44 |

0.041 |

7.2 |

|

30 32 35 38 |

|

82 |

60 |

0.044 |

7.8 |

|

40 42 45 48 50 55 56 |

|

112 |

84 |

0.047 |

9.6 |

|

GIICLD2 |

1600 |

4000 |

38 |

|

82 |

60 |

149 |

116 |

90 |

33 |

6.5 |

2 |

70 |

49 |

42 |

0.085 |

137 |

11.2 |

|

40 42 45 48 50 55 56 |

|

112 |

84 |

0.097 |

14 |

|

60 63 65 |

|

142 |

107 |

0.106 |

16.4 |

|

GIICLD3 |

2800 |

4000 |

40 42 45 48 50 55 56 |

|

112 |

84 |

167 |

134 |

105 |

40 |

7 |

2.5 |

80 |

54 |

42 |

0.16 |

201 |

17.2 |

|

60 63 70 71 75 |

|

142 |

107 |

0.19 |

22.4 |

|

GIICLD4 |

4500 |

4000 |

45 48 50 55 56 |

|

112 |

84 |

187 |

153 |

125 |

41 |

7.5 |

2.5 |

81 |

55 |

42 |

0.29 |

238 |

25.2 |

|

60 63 70 71 75 |

|

142 |

107 |

0.33 |

26.4 |

|

80 85 90 |

|

172 |

132 |

0.38 |

35.6 |

|

GIICLD5 |

6300 |

3750 |

50 55 56 |

|

112 |

84 |

204 |

170 |

140 |

45 |

7.5 |

2.5 |

89 |

59 |

42 |

0.45 |

398 |

31.6 |

|

60 63 65 70 71 75 |

|

142 |

107 |

0.51 |

38 |

|

80 85 90 95 |

|

172 |

132 |

0.58 |

41.6 |

|

100 |

105* |

212 |

167 |

0.67 |

53.9 |

|

GIICLD6 |

9000 |

3300 |

55 56 |

|

112 |

84 |

230 |

186 |

155 |

52 |

8.5 |

3 |

106 |

71 |

47 |

0.75 |

465 |

40.5 |

|

60 63 65 70 71 75 |

|

142 |

107 |

0.840 |

49.8 |

|

80 85 90 95 |

|

172 |

132 |

0.94 |

56.3 |

|

100 110 |

115* |

212 |

167 |

1.07 |

67.5 |

|

GIICLD7 |

14000 |

3000 |

60 63 65 70 71 75 |

|

142 |

107 |

256 |

212 |

180 |

57 |

9 |

3 |

112 |

73 |

47 |

1.43 |

561 |

63.9 |

|

80 85 90 95 |

|

172 |

132 |

1.60 |

74.7 |

|

100 110 120 |

|

212 |

167 |

1.85 |

88 |

|

130 |

135* |

252 |

202 |

2.11 |

106.7 |

|

GIICLD8 |

20000 |

2650 |

65 70 71 75 |

|

142 |

107 |

287 |

239 |

200 |

49 |

8.5 |

3.5 |

112 |

82 |

47 |

2.24 |

734 |

81.7 |

|

80 85 90 95 |

|

172 |

132 |

2.51 |

95.5 |

|

100 110 120 |

|

212 |

167 |

2.88 |

114 |

|

130 140 150 |

|

252 |

202 |

3.25 |

123 |

|

GIICLD9 |

31500 |

2350 |

70 71 75 |

|

142 |

107 |

325 |

276 |

235 |

59 |

9.5 |

3.5 |

125 |

85 |

47 |

4.31 |

956 |

112 |

|

80 85 90 95 |

|

172 |

132 |

4.83 |

130 |

|

100 110 120 |

|

212 |

167 |

5.53 |

156 |

|

130 140 150 |

|

252 |

202 |

6.24 |

181 |

|

160 170 |

175* |

302 |

242 |

7.08 |

212 |

|

GIICLD10 |

45000 |

2100 |

75 |

|

142 |

107 |

362 |

313 |

270 |

76 |

11 |

4 |

149 |

95 |

49 |

7.88 |

1320 |

161 |

|

80 85 90 95 |

|

172 |

132 |

9.52 |

172 |

|

100 110 120 |

|

212 |

167 |

9.52 |

206 |

|

130 140 150 |

|

252 |

202 |

10.25 |

239 |

|

160 170 180 |

|

302 |

242 |

12.22 |

280 |

|

190 200 |

|

352 |

282 |

13.69 |

319 |

注:1、联轴器轴孔组合有Z1/J1、Y/J1。

2、带“*”号的轴孔直径新设计时不用。

|

|

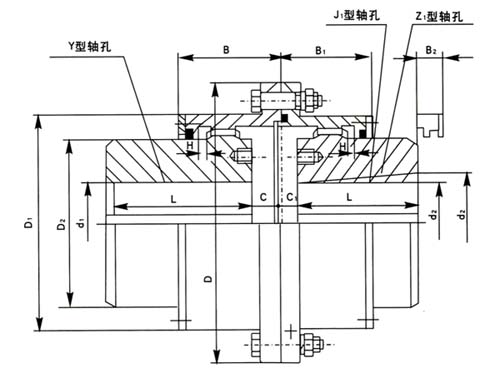

GIICLD型鼓形齿式联轴器基本参数和主要尺寸

|

型号 |

公称扭矩

Tn

(N·m) |

许用转速

[n]

(r/min) |

轴孔直径

d1 d2 |

轴孔长度 |

D |

D1 |

D2 |

C |

C1 |

H |

B |

B1 |

B2 |

转动惯量

(kg·m) |

润滑脂容量

(ml) |

重量(kg) |

|

Y |

Z1 J1 |

|

L |

|

GIICLD1 |

1000 |

4000 |

22 24 |

|

52 |

38 |

127 |

95 |

75 |

33 |

6 |

2 |

66 |

45 |

42 |

0.041 |

107 |

7.2 |

|

25 28 |

|

62 |

44 |

0.041 |

7.2 |

|

30 32 35 38 |

|

82 |

60 |

0.044 |

7.8 |

|

40 42 45 48 50 55 56 |

|

112 |

84 |

0.047 |

9.6 |

|

GIICLD2 |

1600 |

4000 |

38 |

|

82 |

60 |

149 |

116 |

90 |

33 |

6.5 |

2 |

70 |

49 |

42 |

0.085 |

137 |

11.2 |

|

40 42 45 48 50 55 56 |

|

112 |

84 |

0.097 |

14 |

|

60 63 65 |

|

142 |

107 |

0.106 |

16.4 |

|

GIICLD3 |

2800 |

4000 |

40 42 45 48 50 55 56 |

|

112 |

84 |

167 |

134 |

105 |

40 |

7 |

2.5 |

80 |

54 |

42 |

0.16 |

201 |

17.2 |

|

60 63 70 71 75 |

|

142 |

107 |

0.19 |

22.4 |

|

GIICLD4 |

4500 |

4000 |

45 48 50 55 56 |

|

112 |

84 |

187 |

153 |

125 |

41 |

7.5 |

2.5 |

81 |

55 |

42 |

0.29 |

238 |

25.2 |

|

60 63 70 71 75 |

|

142 |

107 |

0.33 |

26.4 |

|

80 85 90 |

|

172 |

132 |

0.38 |

35.6 |

|

GIICLD5 |

6300 |

3750 |

50 55 56 |

|

112 |

84 |

204 |

170 |

140 |

45 |

7.5 |

2.5 |

89 |

59 |

42 |

0.45 |

398 |

31.6 |

|

60 63 65 70 71 75 |

|

142 |

107 |

0.51 |

38 |

|

80 85 90 95 |

|

172 |

132 |

0.58 |

41.6 |

|

100 |

105* |

212 |

167 |

0.67 |

53.9 |

|

GIICLD6 |

9000 |

3300 |

55 56 |

|

112 |

84 |

230 |

186 |

155 |

52 |

8.5 |

3 |

106 |

71 |

47 |

0.75 |

465 |

40.5 |

|

60 63 65 70 71 75 |

|

142 |

107 |

0.840 |

49.8 |

|

80 85 90 95 |

|

172 |

132 |

0.94 |

56.3 |

|

100 110 |

115* |

212 |

167 |

1.07 |

67.5 |

|

GIICLD7 |

14000 |

3000 |

60 63 65 70 71 75 |

|

142 |

107 |

256 |

212 |

180 |

57 |

9 |

3 |

112 |

73 |

47 |

1.43 |

561 |

63.9 |

|

80 85 90 95 |

|

172 |

132 |

1.60 |

74.7 |

|

100 110 120 |

|

212 |

167 |

1.85 |

88 |

|

130 |

135* |

252 |

202 |

2.11 |

106.7 |

|

GIICLD8 |

20000 |

2650 |

65 70 71 75 |

|

142 |

107 |

287 |

239 |

200 |

49 |

8.5 |

3.5 |

112 |

82 |

47 |

2.24 |

734 |

81.7 |

|

80 85 90 95 |

|

172 |

132 |

2.51 |

95.5 |

|

100 110 120 |

|

212 |

167 |

2.88 |

114 |

|

130 140 150 |

|

252 |

202 |

3.25 |

123 |

|

GIICLD9 |

31500 |

2350 |

70 71 75 |

|

142 |

107 |

325 |

276 |

235 |

59 |

9.5 |

3.5 |

125 |

85 |

47 |

4.31 |

956 |

112 |

|

80 85 90 95 |

|

172 |

132 |

4.83 |

130 |

|

100 110 120 |

|

212 |

167 |

5.53 |

156 |

|

130 140 150 |

|

252 |

202 |

6.24 |

181 |

|

160 170 |

175* |

302 |

242 |

7.08 |

212 |

|

GIICLD10 |

45000 |

2100 |

75 |

|

142 |

107 |

362 |

313 |

270 |

76 |

11 |

4 |

149 |

95 |

49 |

7.88 |

1320 |

161 |

|

80 85 90 95 |

|

172 |

132 |

9.52 |

172 |

|

100 110 120 |

|

212 |

167 |

9.52 |

206 |

|

130 140 150 |

|

252 |

202 |

10.25 |

239 |

|

160 170 180 |

|

302 |

242 |

12.22 |

280 |

|

190 200 |

|

352 |

282 |

13.69 |

319 |

注:1、联轴器轴孔组合有Z1/J1、Y/J1。

2、带“*”号的轴孔直径新设计时不用。

|

热卖产品